R&D

Our R&D Center

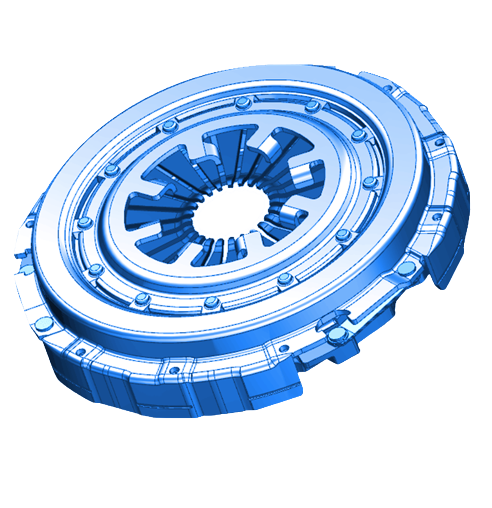

Production Empowered by Technology, Future Shaped by Science

The Hammer Kupplungen R&D Center has been operating with the approval of the Ministry of Industry and Technology since 2015.

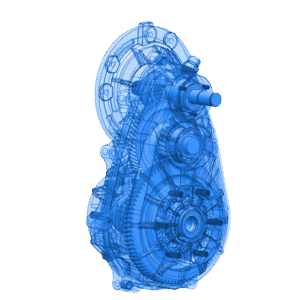

Our product designs are created through CAD-based modeling, supported by CAE analyses, and subjected to thorough testing and validation processes.

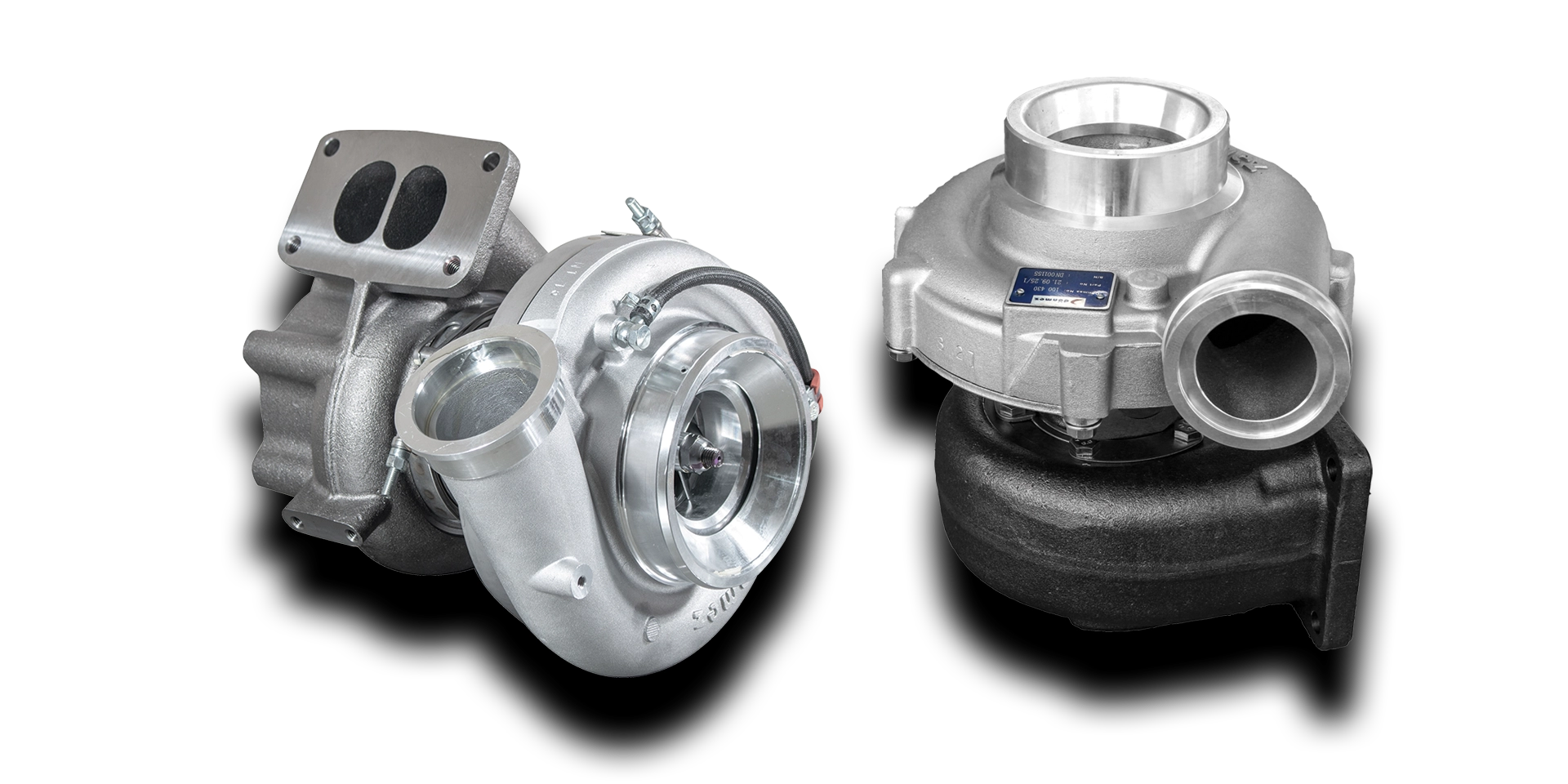

Thanks to the advanced testing equipment in our R&D facilities, all our products undergo top-level control in terms of performance and durability.

Research and Technology Development Unit

Design and analysis studies

Prototyping

Patent applications

Product Development Unit

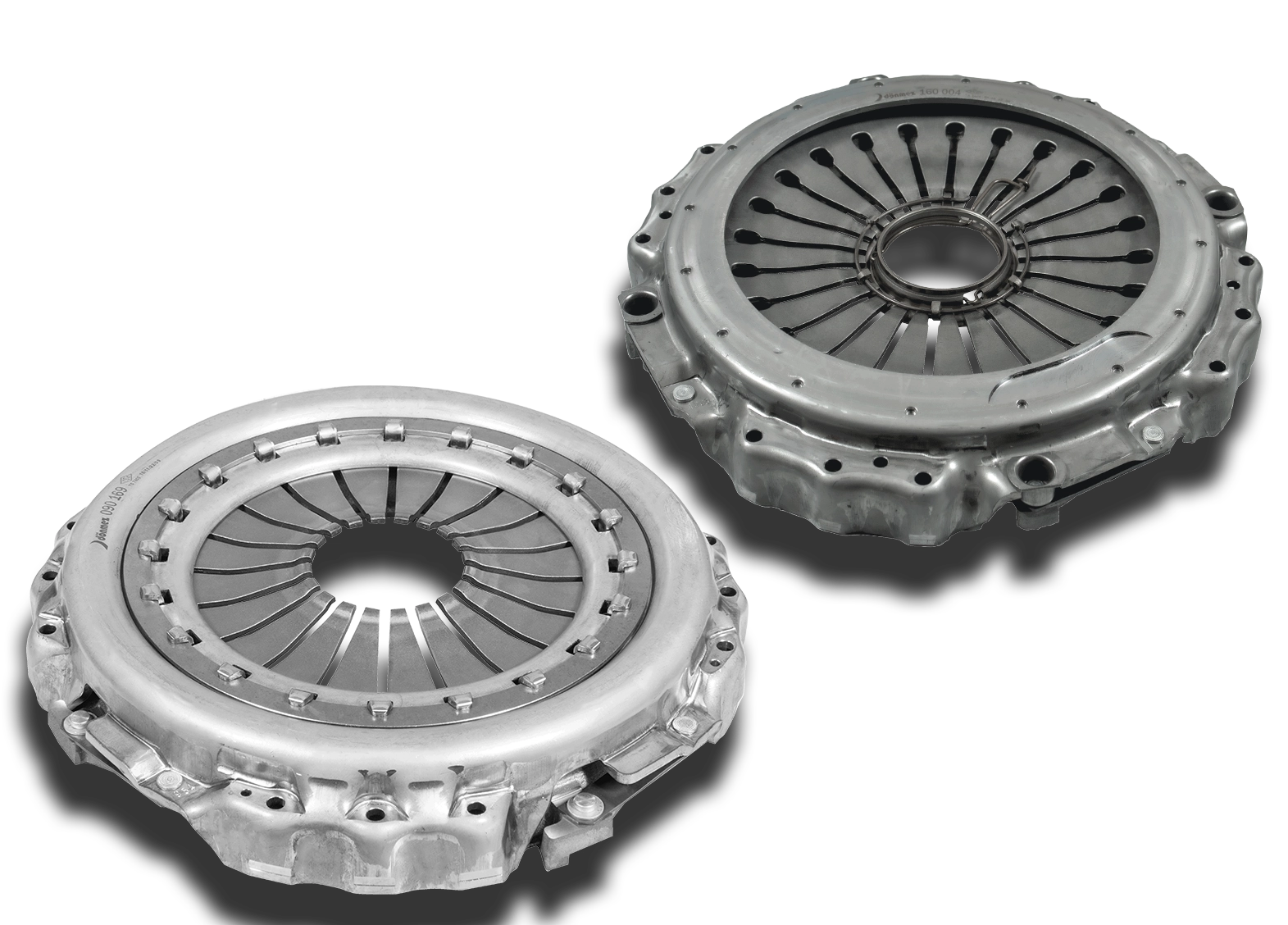

Product design and development

Functional improvements

Patent projects

Test and Validation Unit

Lifetime tests

Durability and static tests

Functional compliance checks

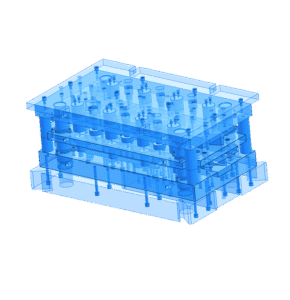

Mold Design and Manufacturing

In this unit, more than 600 molds and fixtures are designed and maintained.

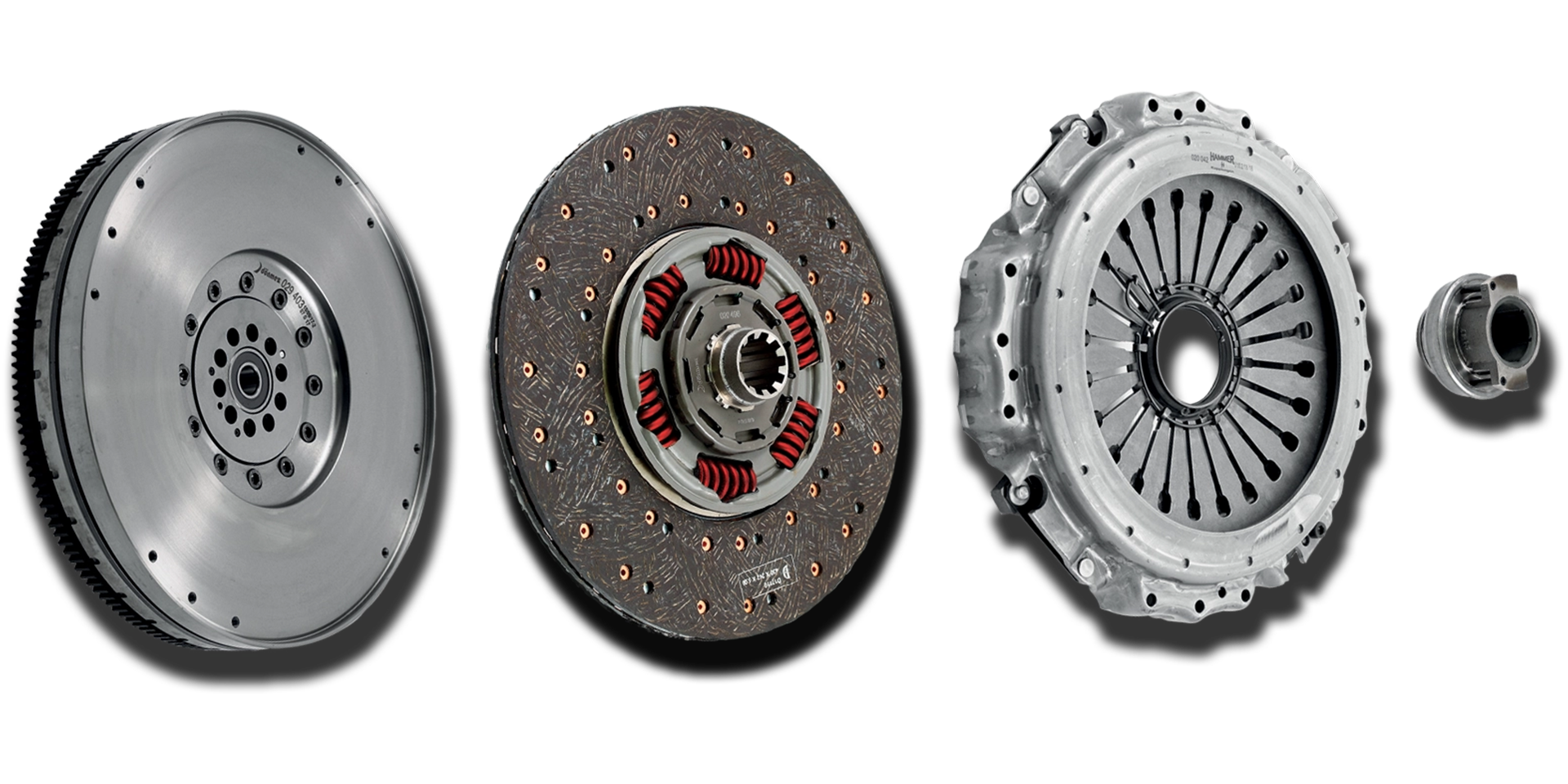

Our Featured Projects

Distortion-free segmentation with low-carbon sheets

Design of sensor-equipped bearing and self-adjusting clutch cover for the first time in Turkey

Production of diaphragm springs heated by induction and hardened in molds

Design and production of discs for Euro 6 engines

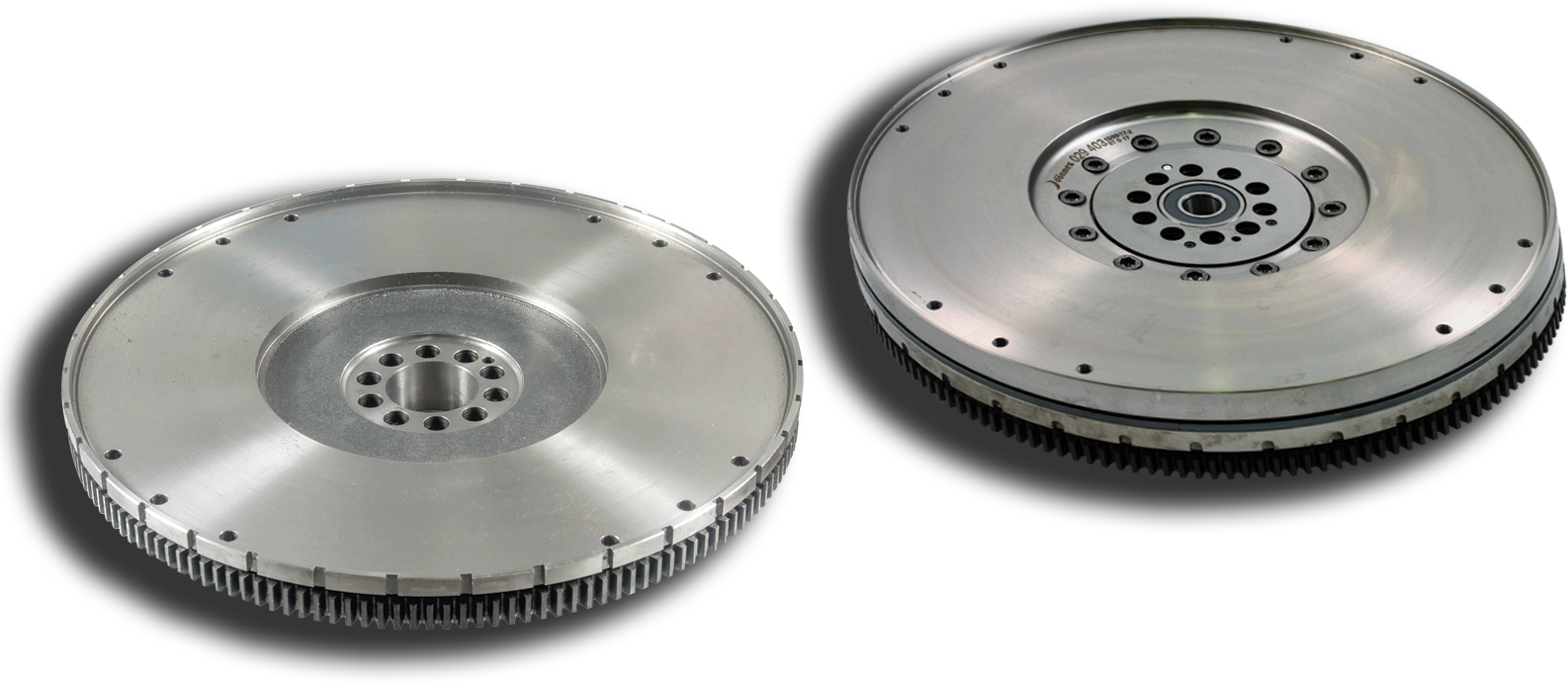

Design and domestic production of 362 mm light truck clutch systems

R&D Laboratory and Testing Infrastructure

The quality control and validation of all our products are carried out with advanced testing equipment within our facilities. Our laboratories enable durability, vibration, and stress tests that measure product performance.

University Collaborations

In our R&D processes, we collaborate with Turkey’s leading universities such as Dokuz Eylül University, Ege University, Katip Çelebi University, Celal Bayar University, and İzmir Institute of Technology. In addition, we have official project partnerships with DESUM and EBİLTEM.