Quality

With the Zero-Defect Principle,

We Produce for a Better Future

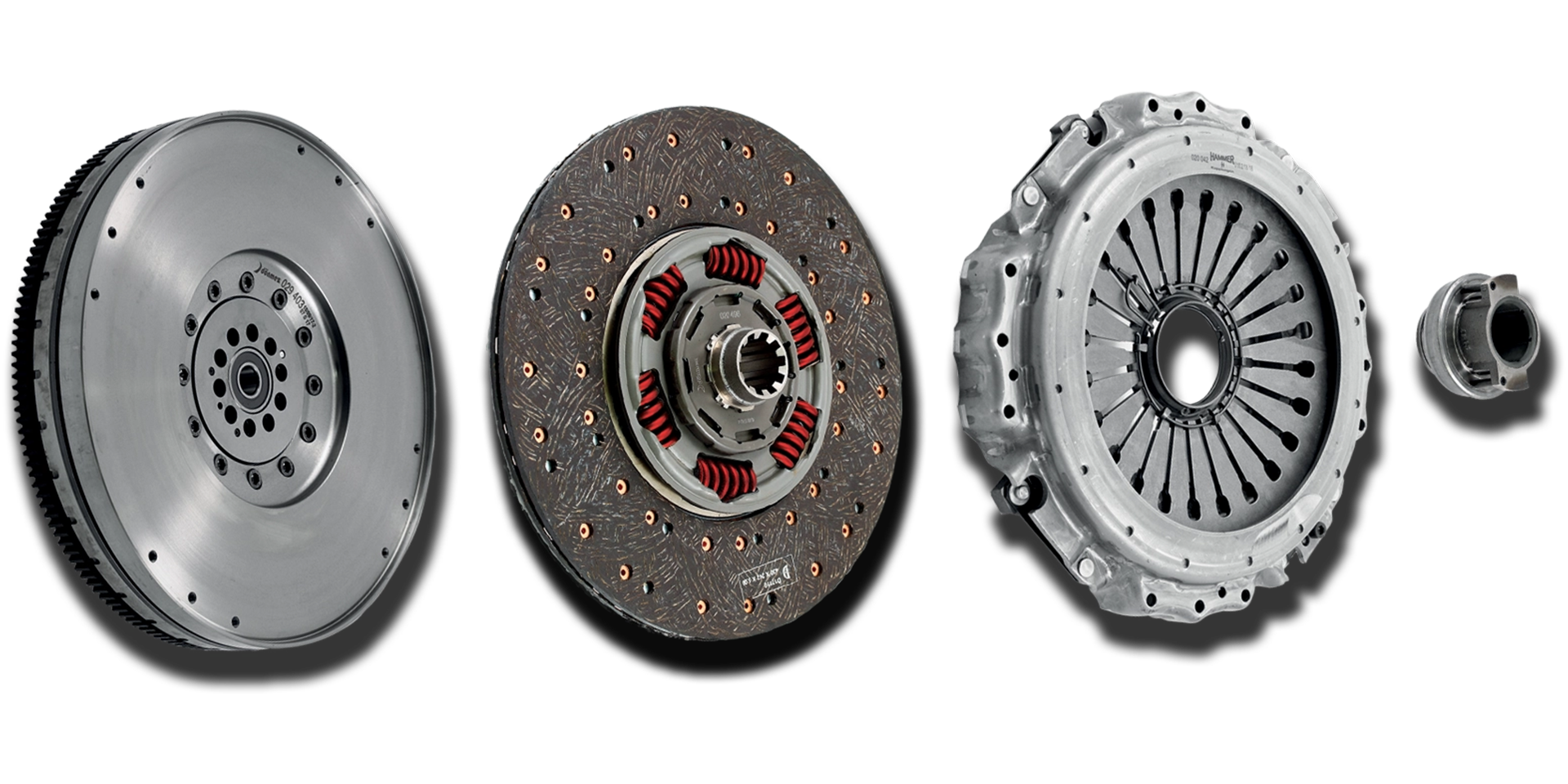

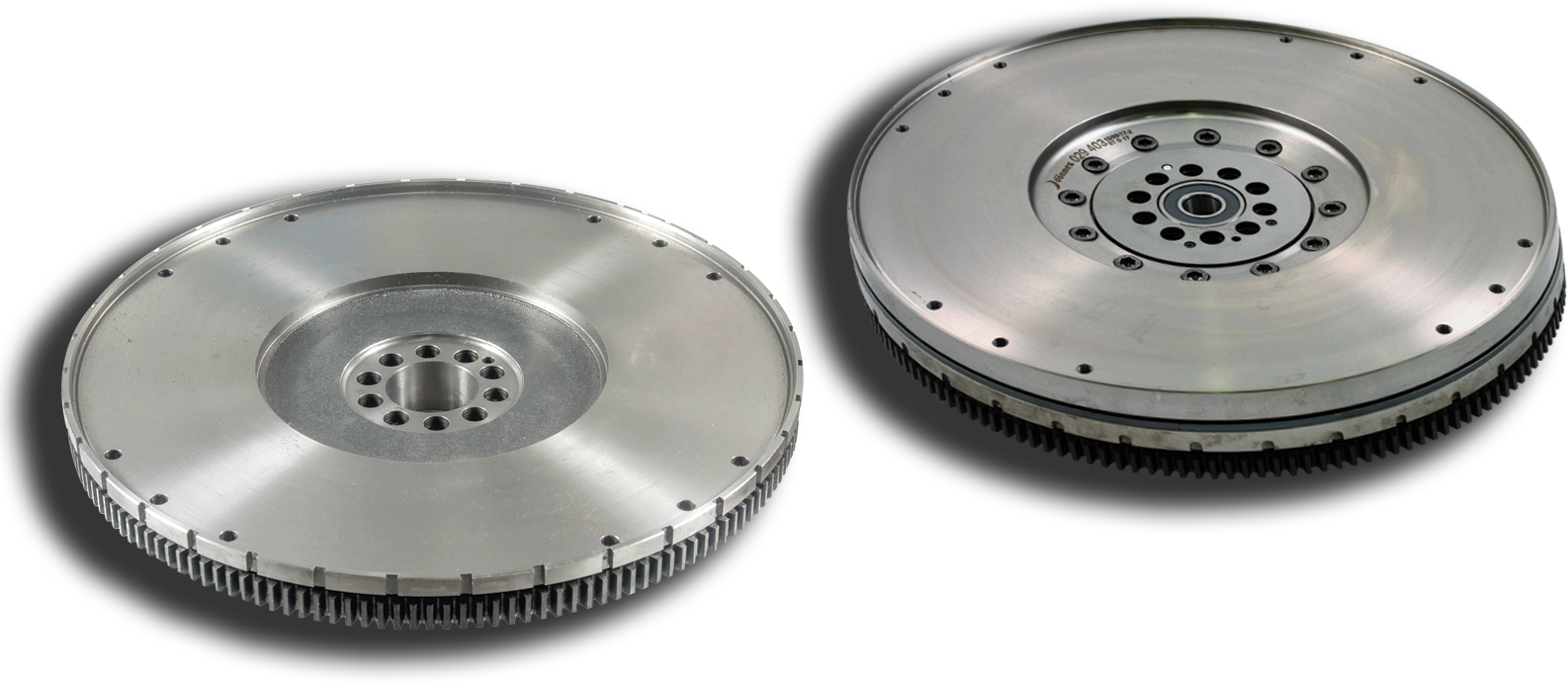

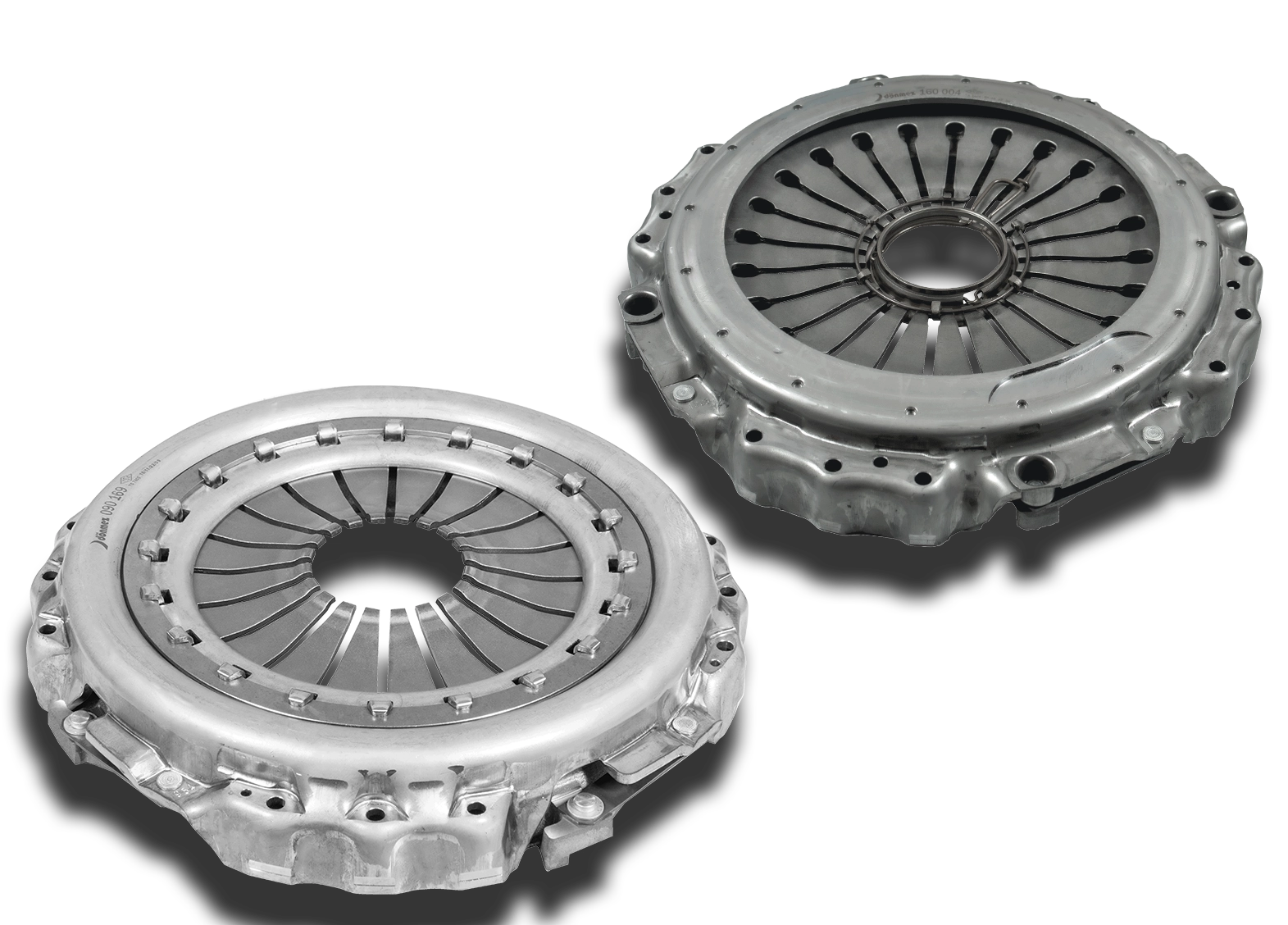

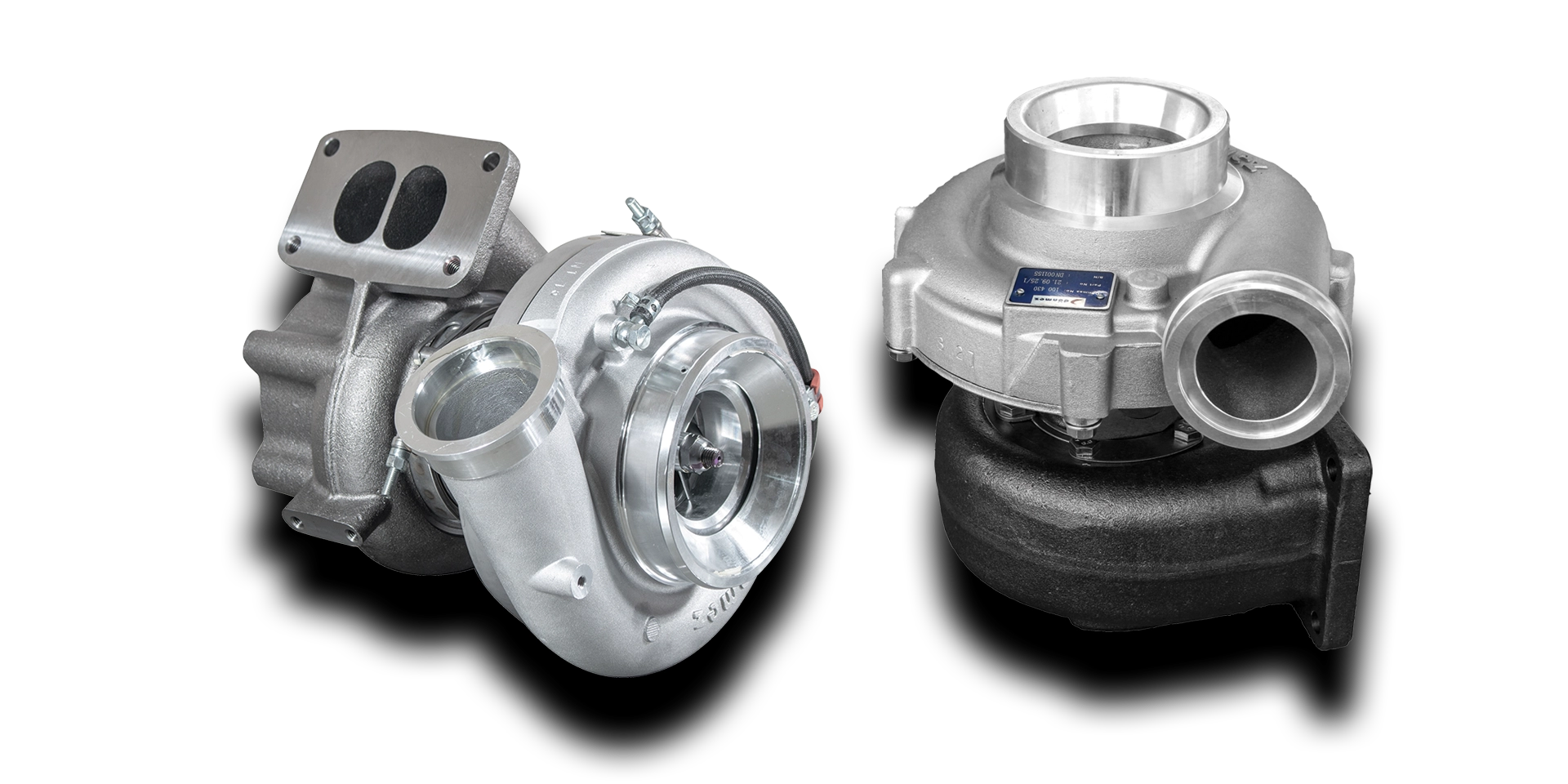

At Hammer Kupplungen, with over 40 years of manufacturing experience, we embrace quality not merely as a goal but as a way of doing business. We aim not only to meet customer expectations but to exceed them. With our competent human resources and reliable stakeholders, we design, manufacture, and deliver globally competitive products with a technological and innovative approach.

Working with the “Zero Defect” principle, we structure all our processes to enhance customer satisfaction. To ensure compliance with quality and performance criteria, we carry out meticulous checks at every stage of production and target minimum resource consumption for a sustainable future.

While continuously encouraging the development of our employees, we sustain uninterrupted process improvement activities through our systematic quality management approach. We draw our strength from our knowledge and our quality from the results achieved in the field.

Better Is Possible:

Every Day, At Every Stage

The Customer Is Our Priority

We design all our processes around customer satisfaction. In line with our sustainability strategy, we aim for maximum efficiency with minimum resource usage.

On-Site Quality Approach

With defined quality controls at every stage, we ensure that only compliant products move on to the next process. We fully comply with legal requirements and standards related to quality and performance.

Continuous Improvement

We regard our employees as our most valuable assets and create suitable environments for their development. Together with all our stakeholders, we embrace continuous improvement to achieve our goals.

Our Capabilities in Quality Management

Capability to ensure high product quality

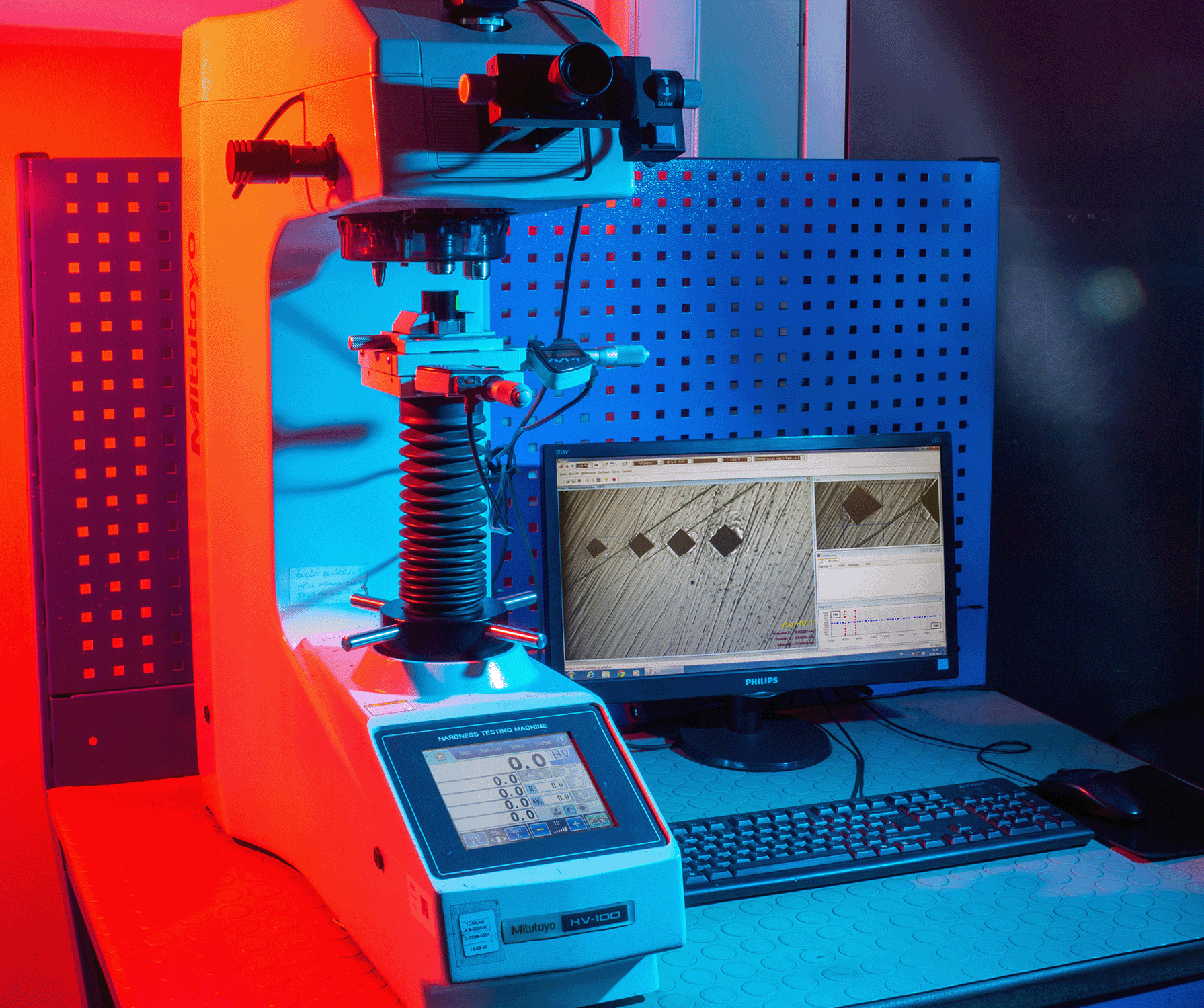

Infrastructure for testing, analysis, measurement, and evaluation

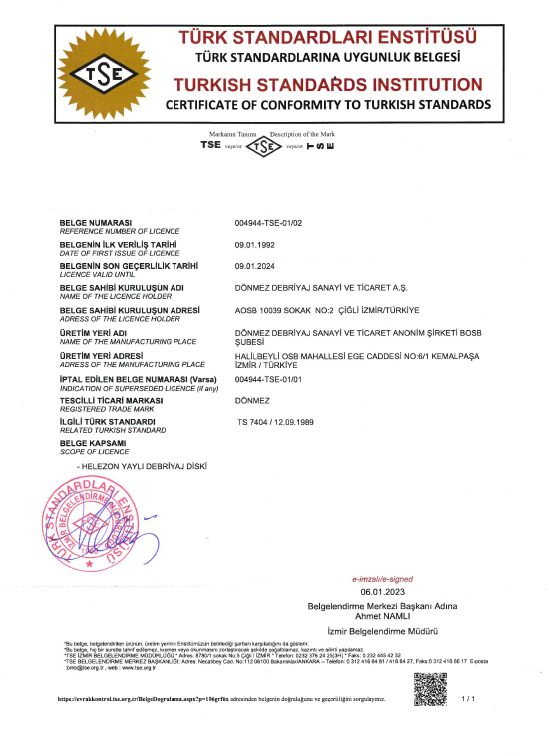

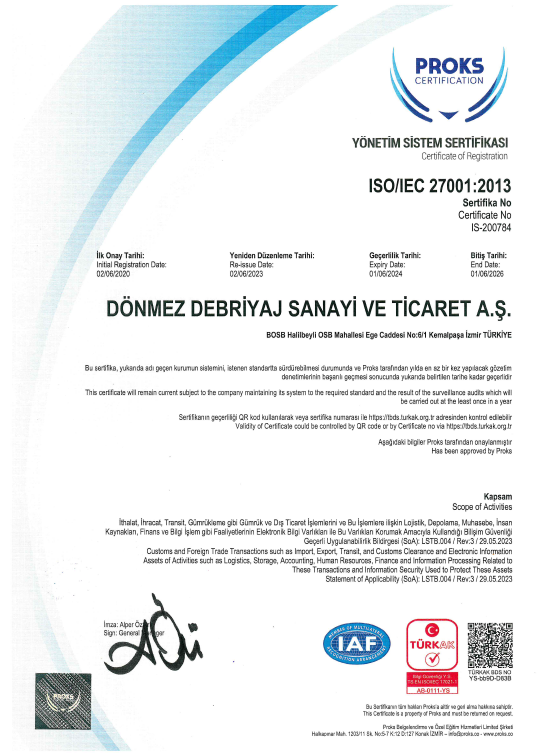

Quality certifications in compliance with international standards

Effective supplier management and raw material control

Management of quality and non-quality costs

Corrective and preventive action processes

Design, process, and product control mechanisms

Customer-centered approach

Ability to generate creative and practical solutions to problems